![]()

Real time X-Ray inspection provides a non-destructive technique to analyze complex structures of varying densities. Internal inspection of a sample can be performed with submicron defect recognition at the highest magnification (5450X) and resolution. Samples can be viewed from 0 – 45 degree angle with capability to view 360 degrees around any position over entire inspection area.

Quick turn BGA rework service.

Your circuit

boards can be reworked, X Ray inspected and shipped within 24 hours of

receipt.

System inspection can provide:

-

Percent of Die Attachment

-

Voiding

-

Solder Sphere Formation

-

Solder Ball Diameter Measurement

-

Micro Cracks

System Capabilities:

- State of the Art Image Inspection

- Submicron spot size

- Automatic void identification and measurement software

- System magnification up to 5450X

- Digital Imaging in multiple formats

- Oblique angle view 0 – 70 degrees

- Inspection

area 18” X 16“

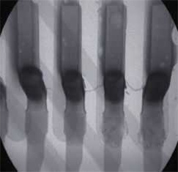

Shorts across solder joint

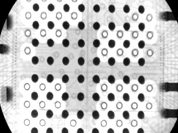

Xilinx Tilt

Memory

chip showing

solder ball and

wirebond connection

![]()

![]()